“Back in the ranks!”

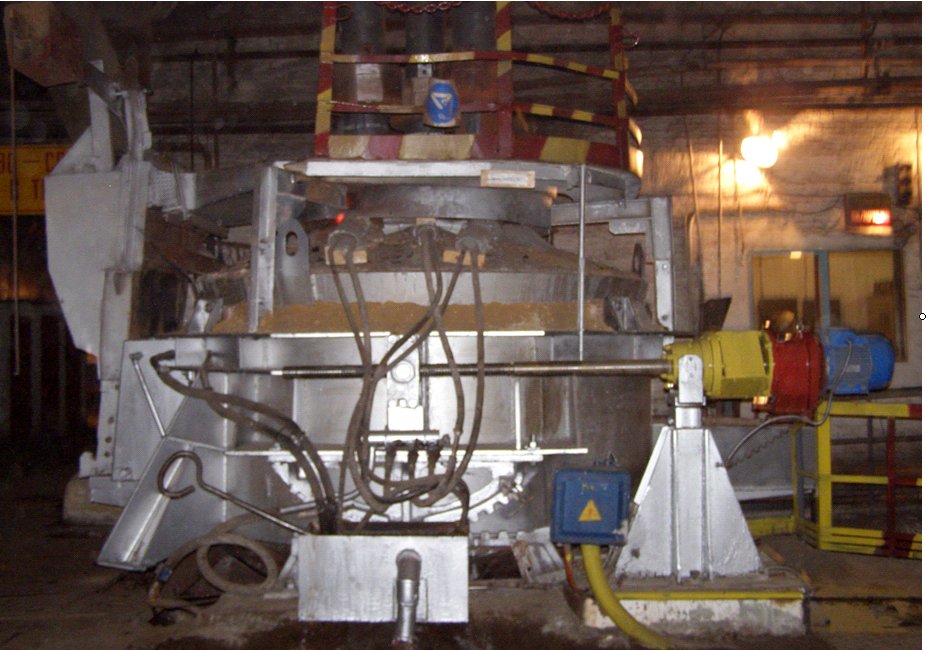

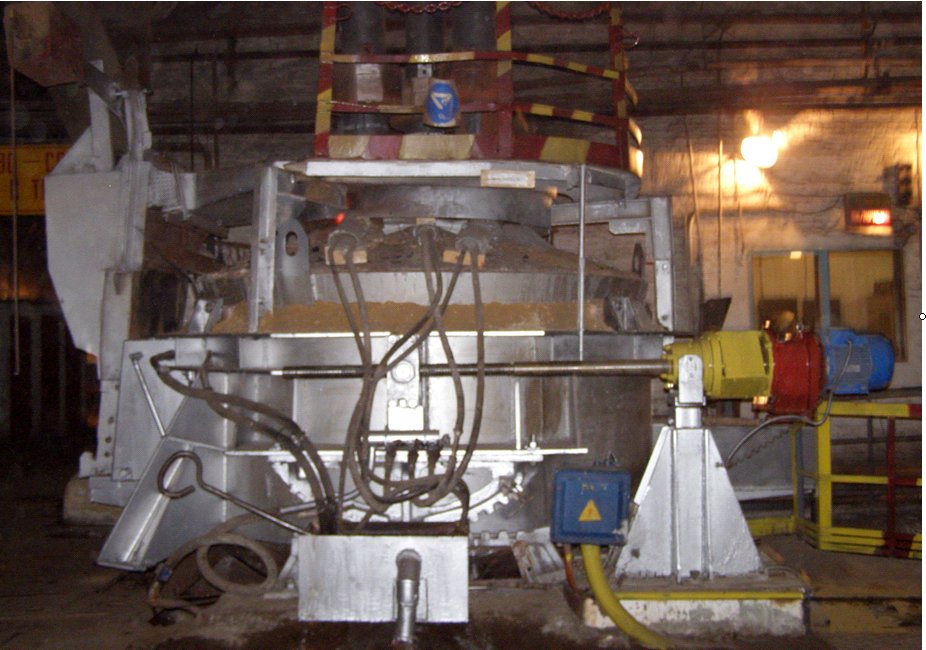

A 5-ton electric arc furnace was restored and put into operation after a long period of inactivity in the molding and cast-iron workshop of the enterprise.

The electric arc furnace consists of a steel casing, which is lined with refractory material from the inside. The vault furnace has openings for three electrodes (the furnace is used three-phase current). Electrodes with a diameter of 300 mm could be graphite. The bottom of the oven is cup-shaped. In the walls of the furnace there is a loading window and an outlet opening with a drain chute.

Direct-action furnaces have a special mechanism that allows you to tilt the furnace toward the flywheel — to release metal, toward the loading window — to release slag. The furnace is designed for melting various, including alloyed, grades of cast iron.